HIGH-QUALITY SOLUTIONS

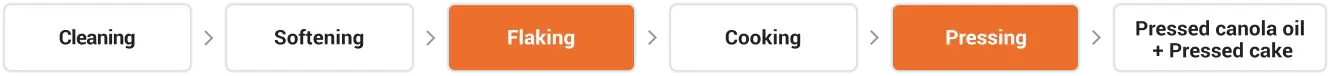

Canola Oil Pressing Process

Roasted canola seeds are fed into the canola oil press machine, where a rotating worm and main shaft push them forward. As the space inside the pressing chamber gets smaller, the pressure inside builds up. The machine has a built-in heater that warms the barrel automatically, and the heat from friction also contributes. This process breaks down the cells in the seeds, releasing the oil.

The oil then moves to a filtering barrel, where a vacuum pump draws it into the barrel, leaving behind solid residues on a filter cloth. This results in the extraction of pure canola oil. From this process, we obtain both crude canola oil and the solid byproduct, pressed oil cake meal, which can be used for other purposes.