Cold pressed peanut oil is produced by reducing high-temperature heating processes. Physical mechanical pressure is used to separate the oil from peanuts, followed by purification and filtration. The entire production process is pollution-free, improving the quality of peanut oil and avoiding harmful substances like trans fatty acids and oil polymers. Active substances in the oil are retained.

Introduction

Since its advent in 1996, cold-pressing technology, led by Nordic countries, has developed rapidly. Cold-pressed oil products are light in color, have minimal phospholipid content, and retain nutritional factors due to the absence of high-temperature processing. Crude oil requires only physical filtration and is known as “green and environmentally friendly nutritional oil.” High-end oils such as peanut oil, rice bran oil, olive oil, camellia oil, linseed oil, and walnut oil can be produced by cold pressing.

Cold Pressed Peanut Oil Process

Cold-pressed peanut oil involves processing peanuts without high-temperature treatments like steaming or stir-frying. The temperature during pressing does not exceed 60°C, resulting in peanut oil. The process includes: cleaning, drying, shelling, removing the red coat, crushing, softening, cooking, pressing, filtration, and packaging. (Read more: peanut oil processing >>)

- Cleaning

The purpose of cleaning is to remove all kinds of impurities in the raw peanut kernel, such as iron, stones, plant stems, and leaves. The impurity content of raw peanuts after cleaning should not exceed 0.1%.

- Drying

Drying is to reduce the moisture of peanut kernels to remove the red coat. Drying requires the moisture to be reduced to less than 4%. To reduce the denaturation of proteins, it is necessary to use a low-temperature drying process, which requires that the temperature of the raw material during the drying process must not be higher than 60 ℃.

- Shelling

The purpose of shelling peanuts before oil extraction is to reduce the adsorption of the shell on the oil and improve the oil yield. Shelling not only improves the processing capacity of the press and reduces the wear and tear on the oil extraction equipment. It can also improve the quality of gross oil and cake meal, which is conducive to comprehensive utilization. (Read more: peanut sheller machine >>)

- Taking off Red Coat

The peanut kernel is composed of the red coat and the seed kernel. The oil protein and other nutrients in peanuts are concentrated in the seed kernel. We can use the dry method to remove the red coat to dry the peanuts to a certain degree, and then use the gum asynchronous double-roller device to strip the red coat from the seed kernel. Depending on the specific gravity of the coats and the kernels, the coats are then separated by an air sorter. The air-selected red coats can be sent to the pharmaceutical industry. In this process, the peanut peeling efficiency is not less than 98%.

- Crushing

Peanuts are large-grained oilseeds and must be crushed before tempering. To achieve the requirements of the broken, must control the moisture content of the oilseed when crushing, the peanut’s suitable crushing moisture is 7% -12%. Crushing is to increase the surface area of the oil, softening temperature and moisture transfer, and softening efficiency, to improve the oil yield. Peanut crushing particle size of 6-8 petals, powder degree does not exceed 5%.

- Softening

Moderate softening of peanut kernels to regulate their moisture content for better steaming. This step may include slight heating to a certain temperature, but it needs to be kept at a low temperature to avoid destroying the nutrients in the peanuts. (Read more: peanut kernels softening cooker >>)

- Cooking

The effectiveness of cooking has a direct impact on the smoothness of the entire oil production process and the oil yield, as well as the quality of the oil and cake. After cooking, the moisture of peanuts should reach 7% and the temperature should be 60℃.

- Pressing

As the oil content of peanuts is relatively high, the first pressing will make the oil content of the cake too high, we can reduce the oil content of the cold pressed cake from 9% to 6.5% through the second pressing. The equipment used for cold pressing is a screw oil press, and the working condition of the press is adjusted to make it suitable for cold pressing of peanut oil.

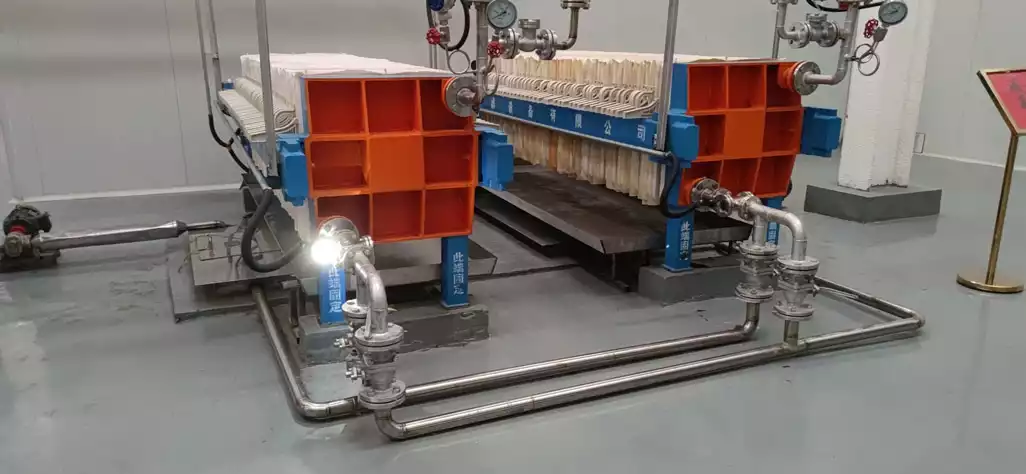

- Filtration

The purpose of filtration is to remove the cake residue contained in the cold pressed oil to obtain edible cold pressed oil. The presence of cake residue in the pressed oil will hurt the transportation and temporary storage of the oil. Therefore, we can use a filter to separate the cake residue from the pressed oil. The cake residue can be sent back to the oil press with a screw conveyor to be pressed again.

- Packaging

The high-quality cold pressed peanut oil obtained after the above steps is finally filled and sealed to become the finished oil in the market.

Cold Pressed Peanut Oil Benefits

- No protein thermal denaturation

- No solvent residue

- Contains natural antioxidant ingredients

- No aflatoxin

- No genetically modified (GMO) ingredients

- No cholesterol ingredients

- No chemicals and preservatives

- Nutrients in peanuts are preserved

- High smoke point, less smoke

cold pressed peanut oil benfits

Cold Pressed Peanut Oil Quality Distinguish

- Color: Light yellow or orange-yellow. Cold-pressed peanut oil is lighter in color compared to hot-pressed.

- Appearance: Good quality peanut oil should be transparent and clear. It may solidify in winter due to a higher melting point, which is normal.

- Smell: Good quality peanut oil has a strong, fragrant peanut kernel smell. Lack of fragrance indicates poor quality.

- Moisture: Refined peanut oil has less moisture, is clear and transparent, and shows no turbidity. Crude or cold-pressed oil has more moisture and sediment.

- Taste: Newly pressed oil tastes delicious, while old oil tastes light. Oil from moldy peanut kernels has a bitter and sour taste.

- Impurities: Good quality oil is bright green and transparent. Opaque oil or oil with many suspended particles contains more impurities.

- Brand: Check the brand of small packaged oil carefully, paying attention to the shelf life and production date.

Conclusion

Cold pressed peanut oil technology has changed the traditional hot-pressing and extraction oil-making process (Read more: solvent extraction of groundnut oil >>). The peanut oil produced is of higher quality, safer, and easier for the human body to absorb. Eating cold-pressed peanut oil can prevent diseases such as arteriosclerosis, cardiovascular disease, diabetes, and digestive system disorders. Huatai Oil Machinery has mature cold pressing technology and can provide a complete peanut oil production line. If you want to know more, please contact us at 0086-159-3728-9608.

Frequently Asked Questions

Cold pressed peanut oil is extracted from peanuts without using high heat, preserving its natural nutrients and flavor.

Some peanut oils are cold pressed, but not all. Peanut oil can be extracted by cold pressing, hot pressing, and extraction. It depends on the production method.

Cold pressed peanut oil is made by extracting oil from peanuts at temperatures below 60°C, without high heat treatments.

Yes, cold pressed peanut oil is considered healthy as it retains more nutrients and antioxidants compared to refined oils.

It varies by product. Check the label on Costco peanut oil to see if it is cold pressed.

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies