Cottonseed Oil Processing

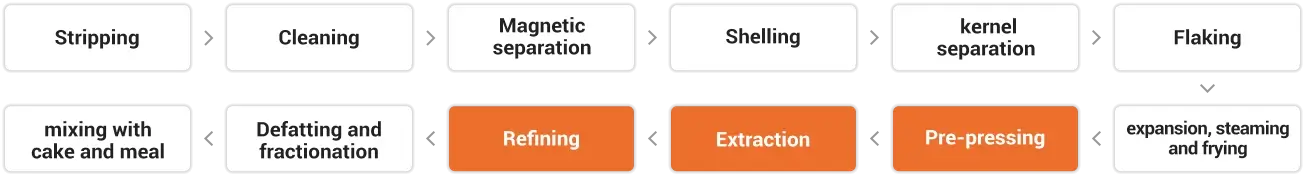

Cottonseed oil is an oil extracted from cottonseed. The traditional cottonseed oil extraction process involves pressing or extraction. The common cottonseed oil processing flow: cottonseed - cleaning - shelling - shell kernel separation - embryo rolling - high moisture steaming - pre-pressing - solvent extraction.

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption. It can generally produce soap, glycerin, ink, lubricating oil, and pesticide solvents in industry.