Introduction

Palm oil is a widely used vegetable oil. The degumming of palm oil is a critical step to ensure the quality and stability of the oil in palm oil processing. In this detailed guide, we will introduce you to the common questions and detailed process of palm oil degumming.

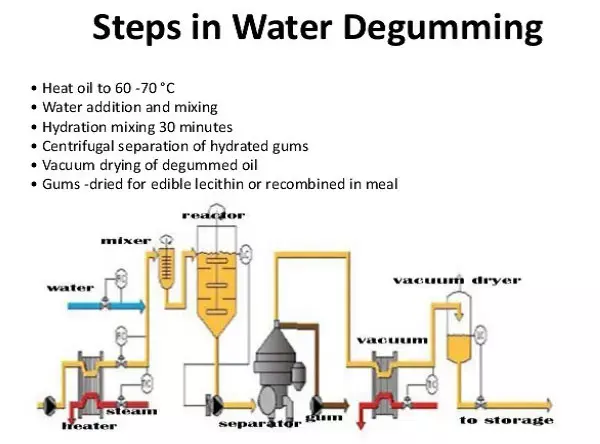

What is water degumming?

Water degumming is a method that utilizes the hydrophilic groups, contained in lipid molecules such as phospholipids. Add a certain amount of hot water or acid to the oil, causing the colloidal water-soluble lipids to absorb water, swell, and condense. And then separate them from the oil by sedimentation or centrifugation.

The water degumming process

Why does palm oil need to degum?

The purpose of palm oil degumming is to remove impurities such as phospholipids and proteins in the oil. Thereby improving the oil’s transparency, stability, and subsequent processing performance.

In addition, the degumming of palm oil also has a certain impact on the subsequent deacidification, decolorization, deodorization, and dewaxing processes.

What are gums in palm oil?

The gums from palm oil mainly include phospholipids and calcium, magnesium, iron, trace metals, and other impurities bound to phospholipids.

What is the degumming process?

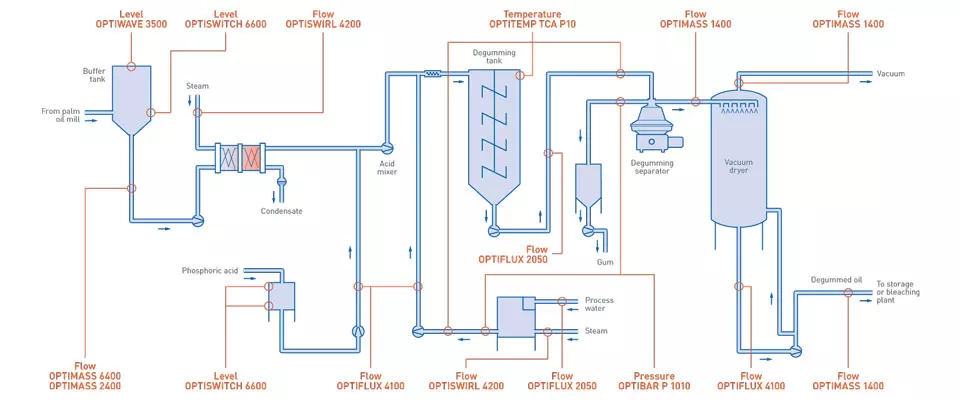

The degumming process of palm oil removes the gums contained in crude palm oil. It includes six steps: crude palm oil preparation, temperature increase, phosphoric acid addition, mixing reaction, sedimentation separation, and vacuum drying.

what is the degumming process

Step1: Crude oil preparation

The first step in the degumming process is to ensure that the quality of palm oil meets the process requirements. This step includes preliminary filtration of the crude oil to remove large particles such as suspended matter, cake crumbs, etc. At the same time, check the key indicators of the crude oil such as phospholipid content, acid value, peroxide value, etc. to provide data support for subsequent processing.

Step2: Raise the temperature

Then, Heat the prepared crude palm oil to 60°C~80°C. Accelerate the dissolution of impurities such as phospholipids, and increase their reactivity with chemical degumming agents. In addition, the appropriate temperature also helps to reduce the viscosity of the oil and promote uniform mixing.

Step3: Add phosphoric acid

After the temperature reaches the required level, add phosphoric acid to the palm oil slowly and evenly. Phosphoric acid can effectively combine with phospholipids to form a complex that is insoluble in oil. Thereby achieving the removal of phospholipids.

The amount of phosphoric acid added needs to be calculated based on the phospholipid content of the crude oil and the process requirements. Too much or too little will affect the degumming effect.

Step4: Mixing reaction

After adding phosphoric acid, mix the palm oil. Ensure phosphoric acid and phospholipids are fully in contact and react. During the mixing process, use an agitator or pump circulation to ensure uniform mixing and sufficient reaction.

The time of the mixing reaction is also one of the key factors affecting the degumming effect, which adjusts according to the specific process conditions.

Step5: Sedimentation and separation

After the mixing reaction, the complex formed by phospholipids and phosphoric acid will gradually settle to the bottom of the oil to form phospholipid feet. At this time, separate the phospholipid feet from the degummed palm oil by static sedimentation or centrifugal separation. This step is crucial to improve the purity and stability of the oil.

Step6: Vacuum drying

Finally, vacuum-dry the degummed palm oil. Vacuum drying can effectively remove trace moisture and volatile impurities in the oil, further improving the quality of the oil.

In a vacuum environment, lowering the temperature for heating can prevent the oil from oxidizing and deteriorating at high temperatures. Ensure that the color, smell, and nutritional value of the oil are well maintained.

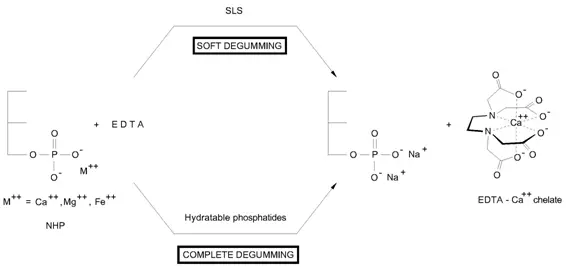

What chemicals are used in degumming?

EDTA (ethylenediaminetetraacetic acid) can remove metal ions (such as Ca²⁺, Mg²⁺, Fe²⁺) in non-hydratable phospholipids through complexation. It is made free and enters the water to be removed, thus effectively removing phospholipids.

What chemicals are used in degumming

Conclusion

In conclusion, the process of degumming of palm oil is water degumming. After degumming, the phospholipid content of palm oil is less than 5ppm-10ppm, the iron, magnesium, and calcium metal content is less than 0.2%, and the free fatty acid content is less than 2%, thus ensuring the subsequent palm oil refining process.

References:

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies