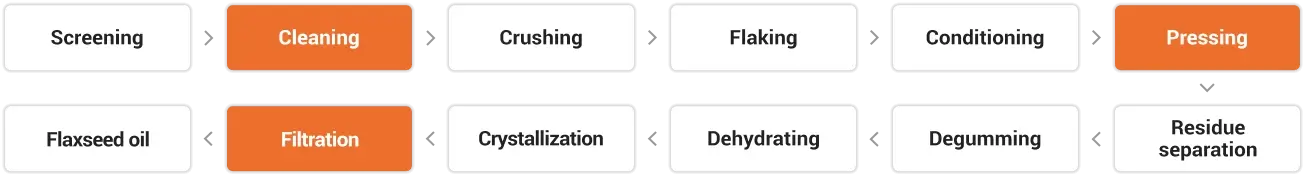

Flaxseed Pretreatment

After obtaining the flaxseed, it needs to be treated first. The purpose is to remove impurities (such as dust, straw, stones, metal fragments, etc.) and moisture on the surface of the flaxseed, and to maintain the integrity of the flaxseed. Common raw material processing steps include washing, sieving, and drying. The washing process can involve washing with water to remove the seed coat and other impurities. The purpose of sieving is to remove larger impurities and bad seeds. Drying serves to volatilize the water out of the flaxseed and improve the quality of the oil.