Introduction

Palm oil is in almost everything we use daily, from cooking oil to cosmetics. Understanding its production process is not just fascinating but also crucial, given the controversies surrounding its environmental impact. So, let’s dive in and explore how palm oil is made, step by step.

What is palm oil?

Palm oil is a versatile vegetable oil derived from the fruit of the oil palm tree (Elaeis guineensis). It’s known for its high yield and low production cost compared to other vegetable oils. This reddish oil is rich in saturated fats and is used in various food and non-food products. Since the 1960s, global palm oil production has increased dramatically, from just 2 million tonnes to around 80 million tonnes by 2020. This represents a 40-fold increase over five decades.

Where does palm oil come from?

Palm oil primarily comes from countries with tropical climates, such as Indonesia and Malaysia, which together produce about 85% of the world’s palm oil. Among them, Indonesia is generating 34.5 million tons annually. The oil palm tree thrives in these regions due to the warm temperatures and abundant rainfall.

Why is palm oil everywhere?

Palm oil’s ubiquity can be attributed to its versatility and cost-effectiveness. It’s used in food products like margarine, chocolate, and ice cream, as well as in household items such as soap, shampoo, and cosmetics. Its ability to remain solid at room temperature makes it ideal for many applications, replacing partially hydrogenated oils that contain trans fats.

What industry can use palm oil?

Various industries rely on palm oil, Over two-thirds (68%) of palm oil is used in food products, while 27% is used in industrial applications and consumer products such as soaps, detergents, and cosmetics.

- Food Industry: As a cooking oil and ingredient in processed foods.

- Cosmetics Industry: In soaps, shampoos, and lotions.

- Biofuel Industry: As a component of biodiesel.

- Pharmaceutical Industry: In the production of certain medications.

What is the problem with palm oil?

The primary issues with palm oil production are environmental and social. Large-scale deforestation, habitat destruction, and loss of biodiversity occur when rainforests are cleared for palm plantations. This process also contributes significantly to greenhouse gas emissions. Social problems include poor working conditions and land rights conflicts with indigenous communities.

Why don’t we just switch to an alternative vegetable oil?

Palm oil’s ubiquity can be attributed to its versatility and cost-effectiveness. It’s used in food products like margarine, chocolate, and ice cream, as well as in household items such as soap, shampoo, and cosmetics. Its ability to remain solid at room temperature makes it ideal for many applications, replacing partially hydrogenated oils that contain trans fats.

The palm oil consists of about 49.3% saturated fat, and hydrogenated palm oil has even more, at 88.2%. It is the most productive oil crop, yielding up to 20 times more oil per hectare than alternative crops. This efficiency has likely spared significant environmental impacts that would have occurred if other crops were used to meet the demand.

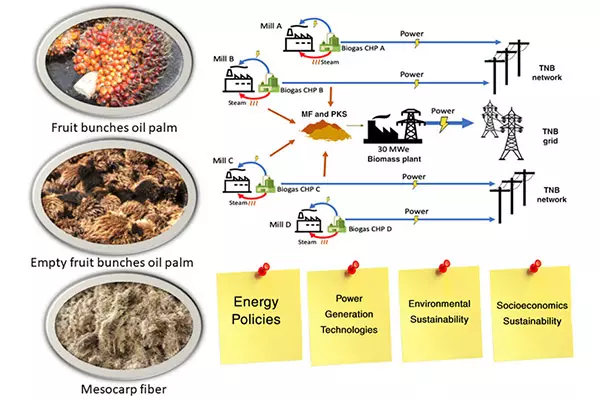

What is the process of making palm oil?

The production of palm oil involves several key steps, starting from the harvest of palm fruit bunches to the extraction and refining of the oil. Here’s a detailed breakdown:

Step1: Palm kernel pretreatment

Palm bunch reception

The process begins with the reception of fresh fruit bunches (FFB) from the plantations. These bunches are transported to the mill where they are checked for quality and weighed. Ensuring the quality of the fruit at this stage is crucial for producing high-quality oil.

Sterilization

Next, the FFB is sterilized using high-pressure steam. This step serves multiple purposes: it softens the fruit, making it easier to strip away from the bunch; it helps in reducing enzyme activity that could spoil the oil; and it kills bacteria and other microorganisms that could cause fermentation.

Threshing

The sterilized fruit bunches are then sent through a threshing machine, which separates the fruit from the bunches. This mechanical process involves rotating drums or beaters that strip the fruits off the stalks.

Digesting & Pressing

The separated fruits are then transferred to a digester, heated, and stirred to break down the pulp. This step is essential for releasing the oil contained in the mesocarp (the fleshy part of the fruit). After digestion, the fruit mash is pressed to extract the crude palm oil (CPO). The pressing is typically done using screw presses, which apply pressure to squeeze out the oil.

Oil clarification

The crude palm oil extracted from the press contains impurities such as water, fibers, and other solids. These impurities are removed through a clarification process, usually involving a centrifuge separating the oil from the non-oil components.

Palm kernel recovery

After the oil extraction, the remaining kernel is recovered from the fruit. The kernels are then cracked to remove the shell, leaving behind the palm kernels. These kernels undergo further processing to extract palm kernel oil, a valuable byproduct used in various applications, including food products and cosmetics.

Step2: Palm oil refinery plant

The crude palm oil undergoes refining to improve its quality and make it suitable for consumption and industrial use. The refining process involves several steps:

Degumming

The first step in refining palm oil is degumming. This process targets the removal of phospholipids and other impurities that are gum-like. To achieve this, the crude palm oil is mixed with water or an acidic solution. The interaction between the water or acid and the oil causes the gums to coagulate, making them easier to separate. The degummed oil is then dried to remove any residual moisture.

Deacidification

Following degumming, the oil undergoes deacidification. This step is crucial for neutralizing free fatty acids, which can affect the taste and stability of the oil. An alkaline solution, commonly sodium hydroxide, is used to react with the fatty acids, forming soapstock that can be easily removed. The result is a milder, more palatable oil that is less prone to oxidation.

Deodorization

The third step is deodorization, which serves to eliminate any undesirable odors and flavors from the oil. This is accomplished by heating the oil under a vacuum, which lowers the boiling point of the volatile compounds responsible for the unwanted smells and tastes. Steam is then passed through the heated oil, stripping away these compounds. The deodorized oil has a neutral scent and flavor, making it more versatile for various applications.

Bleaching

The final step in the refining process is bleaching. The objective here is to remove color pigments to produce a clear and bright oil. This is done by mixing the oil with bleaching earth or activated carbon, which has a high affinity for pigments and other impurities. These substances act like a sponge, absorbing the unwanted components. The mixture is then filtered, and the clean, bleached oil is collected.

Step3: Palm oil fractionation plant

The final stage in the production process involves fractionation, where the oil is separated into solid and liquid components.

Heating

In the heating phase, the refined palm oil is carefully brought to a precise temperature. This step is vital because it prepares the oil for successful fractionation. The temperature is meticulously controlled to ensure that the triglycerides within the palm oil melt appropriately, allowing for the correct separation of the different fractions based on their melting points.

Filtration

Once the oil has been heated, it moves on to the filtration stage. During filtration, the oil is passed through a filter that separates the solid fraction, known as stearin, from the liquid fraction, called olein. The stearin solidifies at higher temperatures compared to olein, which remains liquid. This physical property allows for their separation through filtration.

- Stearin: The solid part, stearin, is utilized in the production of products that require a more solid consistency, such as margarine and shortening. It’s valued for its higher melting point, making it ideal for creating spreads that maintain their shape at room temperature.

- Olein: The liquid part, olein, is what we commonly refer to as cooking oil. It’s preferred for its lower melting point, which makes it a versatile oil for frying, baking, and other culinary uses.

What are the environmental impacts of palm oil production?

Palm oil production has significant environmental impacts, including deforestation, habitat destruction, and biodiversity loss. The clearing of rainforests for palm plantations releases large amounts of carbon dioxide, contributing to climate change. Additionally, the loss of habitats threatens the survival of many species, including orangutans, tigers, and rhinos.

In a UK consumer survey, 41% of respondents viewed palm oil as ‘environmentally unfriendly,’ a much higher percentage than for other vegetable oils. This has led to a growing number of companies eliminating palm oil from their products.

How can palm oil production be made more sustainable?

To mitigate the negative impacts, sustainable palm oil production practices can be implemented, such as:

- Adopting RSPO (Roundtable on Sustainable Palm Oil) standards: Ensuring that palm oil is produced in an environmentally and socially responsible manner.

- Increasing yield on existing plantations: Improving agricultural practices to produce more oil from the same amount of land.

- Protecting primary forests: Implementing strict regulations to prevent deforestation.

- Promoting transparency: Encouraging companies to disclose their sourcing practices and supply chain information.

Conclusion

Palm oil production is a complex process with significant environmental and social implications. While it plays a vital role in the global economy, its production must be managed responsibly to minimize its negative impacts. By understanding the steps involved and the challenges faced, Huatai can make informed choices and support sustainable practices.

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies