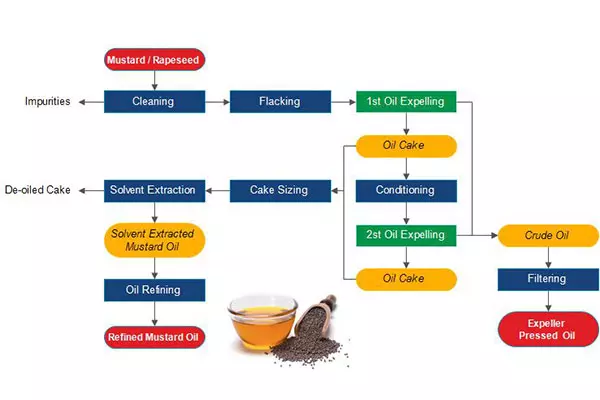

Mustard Oil Production Process

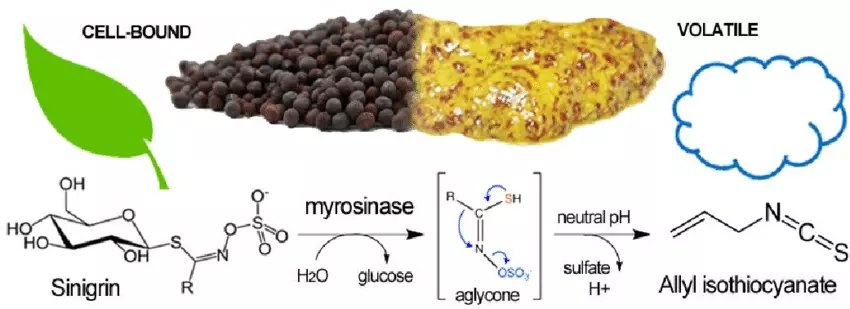

Mustard oil is extracted from mustard seeds and has a strong pungent taste. Its main component is allyl isothiocyanate (more than 90%), which is mainly used in food seasonings such as seasonings and sauces. In this article, we will introduce the production process of mustard oil in detail step by step.

Mustard oil has two types: black mustard oil and white mustard oil. Black mustard oil is made by pressing the seeds of black mustard (also known as rod mustard) to form a cake, and then steam distilling it. White mustard oil is made by solvent extraction from the seeds of white mustard (also known as yellow mustard).

- Raw material selection

First, to ensure the quality of mustard oil, you need to choose mustard seeds with full seeds, large grains, and dark yellow color as raw materials.

- Soaking

Secondly, weigh the mustard seeds, add warm water (about 37℃) about 6-8 times the amount of mustard seeds, and soak for 25-35 hours.

- Crushing

Then, put the soaked mustard seeds into a grinder and grind them. The finer the better, to form a mustard paste.

- Acidification

Next, you need to adjust the pH value of the mustard paste to about 6 by using white vinegar.

- Hydrolysis

Put the mustard paste with the correct pH into the hydrolysis container. Then, place the container in a water bath. Make sure the water bath is at a constant temperature. Under the insulation condition of about 80℃, hydrolyze for 2-2.5 hours.

- Distillation

Next, place the mustard paste in the distillation device and use steam distillation to extract the spicy substances.

- Separation

Initially, the blend of oil and water undergoes distillation. Subsequently, an oil-water separator to employed to differentiate the two. This process results in the extraction of mustard essential oil.

- Blending

Mustard essential oil is subsequently mixed and evenly incorporated with vegetable oil, adhering to the specified formula proportion, to yield mustard oil.

- Filling

Finally, fill the mustard oil into a glass bottle that has been cleaned, disinfected, and dried in advance, labeled, and sealed to obtain the finished product.

Main Equipment

Constant temperature water bath, grinder, distiller, oil-water separator, soaking container, blending container, and filling machine.

Quality Standard

Mustard oil should be a light yellow oily liquid with a strong spicy and tear-inducing taste.

How to make mustard oil from seeds

Precautions

- Hydrolysis is in a closed container to retain the flavorful components and prevent evaporation.

- Try to steam out all the spicy substances during distillation to reduce losses.

- Store mustard oil in a cool, dark place to prevent it from reacting with water and affecting its quality.

Conclusion

In general, the processing flow of mustard oil is mustard seeds-soaking-crushing-acidification-hydrolysis-distillation-separation-blending-filling. This process involves physical methods such as soaking and crushing. It also involves chemical methods like adding acid and breaking down molecules. Additionally, this process uses distillation techniques.

Huatai Oil Machinery can provide mustard oil production lines and turnkey projects of various sizes. Should you wish to establish a mustard oil production facility, kindly reach out to us promptly.

External Resources:

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies