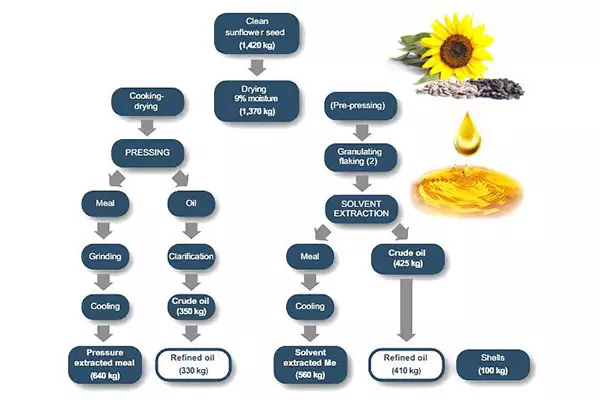

Sunflower oil is a common vegetable oil extracted from sunflower seeds. The sunflower oil production process includes cleaning, shelling, kernel separation, cooking, pressing, filtering, extracting, refining, and packing. Here’s a step-by-step guide to help you understand how sunflower oil is made.

- Sunflower Seeds Cleaning Preparation

First, you need to clean the sunflower seeds to remove impurities and dirt. Use special cleaning equipment like vibrating screens, stone removers, and magnetic separators. The vibrating screens remove light impurities such as leaves, while stone removers remove stones and clods. Finally, magnetic separators absorb metallic impurities like iron blocks, ensuring you have cleaner sunflower seeds.

- Shelling and Kernel Shell Separation

Next, shell the sunflower seeds to separate the hulls from the kernels. Use a sheller to crack the shells and a kernel shell separator to obtain clean sunflower kernels. Removing the hulls increases the oil yield and ensures high-quality sunflower oil.

- Sunflower Seeds Cooking

Now, adjust the temperature and humidity of the sunflower seeds using a cooker. This step ensures the seeds are in optimal condition for pressing, which improves the oil yield.

- Sunflower Seeds Pressing

Press the cooked sunflower seeds to extract the oil. You can use either cold pressing or hot pressing methods. Cold pressing involves mechanically pressing the seeds to extract the oil, while hot pressing involves heating the seeds before pressing to make oil extraction easier. Continuously add the heated sunflower seeds meal to the oil-making machine, which has a slotted barrel that applies high pressure (from 69,000 to 200,000 kilopascals) to squeeze out and recover the oil through the slots.

- Sunflower Seeds Oil Filtering

Filter the pressed sunflower oil to remove impurities and residues. Use a physical filtration method with a plate and frame filter to remove moisture and impurities from the oil.

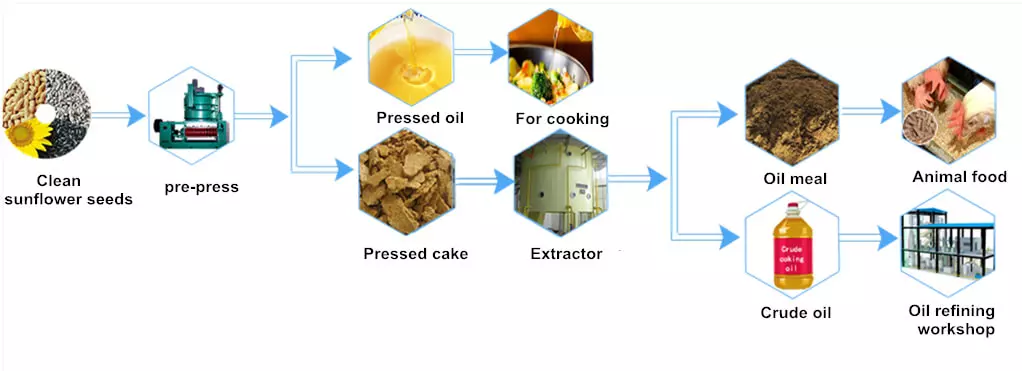

- Crude Oil Extraction

Dissolve the oil from the oil cake using hexane and other solvents to maximize output. Distill the dissolved oil to recover it, and then collect the oil at the end of the process. Use equipment designed to enhance the quantity of the solvent and reduce the time taken in the oil processing.

- Solvent Traces’ Removal

Recover and reuse a good percentage of the solvent used after extracting the oil. Strip and recover the residual solvent from the flakes using heat and steam. At this stage, you get desolventized fragments ready for the market. Further, refine the sunflower oil to make it more edible.

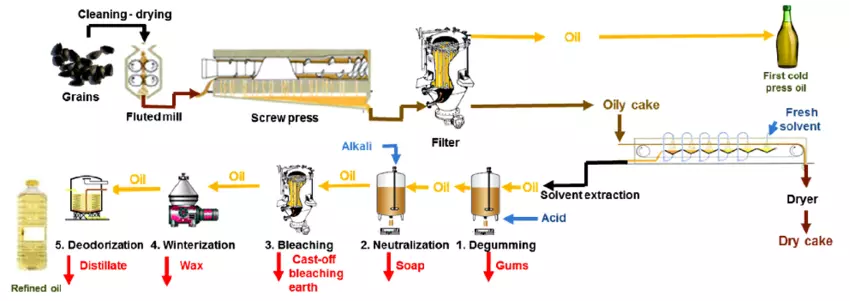

- Sunflower Seeds Oil Refining

Use chemical refining methods to absorb the odor and impurities into an adsorbent, and then separate the adsorbent from the oil through filtration. Improve the oil’s color, flavor, odor, and stability by bleaching, degumming, deodorizing, and neutralizing it. Heat the oil to around 40-85 degrees Celsius and mix it with carbonates or chlorides of sodium. This process eliminates pollutants like free fatty acids, pro-oxidants, and phosphatides. Additionally, some oils may be de-waxed or improved to alter their melting features.

- Sunflower Seeds Oil Packing

Finally, pack the liquid and solid products in various quantities ready for the market. The byproducts from the entire process can be directly used or further improved for extended use.

The above steps outline the process of making sunflower oil. Some steps can be customized based on specific requirements. This process also applies to other vegetable seeds and nuts, such as cottonseeds, peanuts, and palm kernels.

The equipment and machinery needed for a sunflower oil processing plant vary based on the scale of production. For small-scale sunflower oil processing, the equipment is relatively simple and easy to operate, with low investment costs and considerable profits. If you’re interested in sunflower oil processing, please contact us for more detailed information!

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies