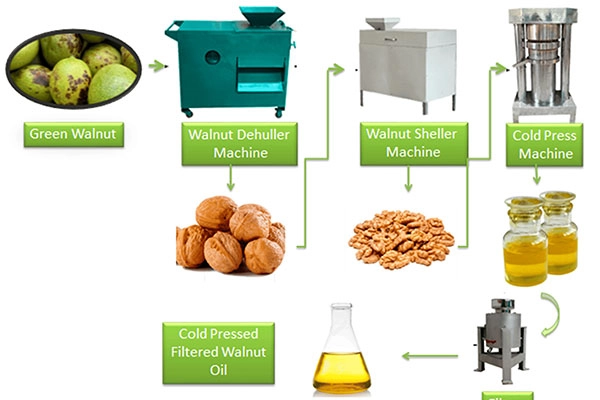

Walnut oil is a common edible oil extracted from walnuts. It is rich in unsaturated fatty acids (such as Omega-3 and Omega-6), vitamin E, and a variety of nutrients, which are beneficial to human health. The walnut oil production process generally includes raw material cleaning, crushing, cooking, pressing, precipitation, filtering, deodorization, and packaging. In this article, we will introduce you to the production process of walnut oil in detail.

- Selecting High-Quality Walnuts

First of all, the production of walnut oil requires high-quality walnuts as raw materials. You should choose walnuts that are free of mold, and pests and suitable maturity as production raw materials. Because immature or over-ripe walnuts will affect the taste and nutritional value of the oil.

- Cleaning and Drying

Secondly, before production begins, you need to clean and screen the walnuts to remove impurities and bad fruits. Cleaning is to remove surface dust, impurities, and residual pesticides. After cleaning, the walnuts are dried naturally or mechanically. Reduce the water content of the walnuts to an appropriate level for subsequent processing.

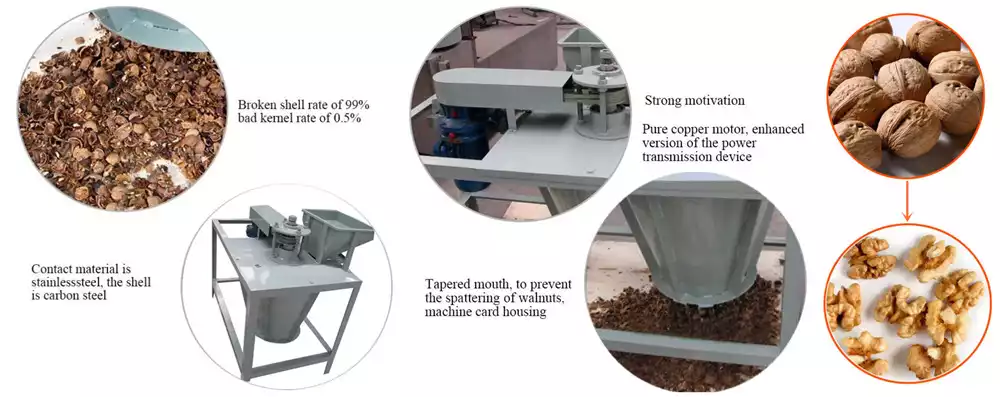

- Walnuts Crushing

Next, use a shelling machine to remove the walnut shell and retain the walnut kernel. Subsequently, send the walnut kernels to the crusher for crushing. They are crushed into particles of a certain size so that the oil can be fully released during pressing or solvent extraction.

- Walnut Kernels Steaming

Then, send the crushed walnut kernels to the steaming pot and steaming at a certain temperature. The purpose of steaming is to destroy the protein enzymes in the walnut cells, thereby preventing corruption and oxidation and improving the quality and stability of the oil.

- Walnut Oil Pressing

Then, place the steamed walnut kernels in the oil press for pressing. In this process, the oil in the walnut kernels is separated to form preliminary walnut oil. The pressing technology and process will directly affect the quality of the final walnut oil.

Usually, there are two ways of pressing: cold pressing and hot pressing. Cold pressing refers to pressing at low temperatures, which can maintain the nutrients and aroma of walnut oil, but the yield is low. Hot pressing is pressing at high temperatures, which can increase the yield but will affect some of the nutrients. You can choose the pressing method that suits you according to different needs. - Precipitation

Because the walnut oil obtained initially will contain some impurities and residues, it needs to precipitation process. You can leave the walnut oil for a while to let the impurities settle to the bottom naturally. Then separate the clear upper oil and filter it.

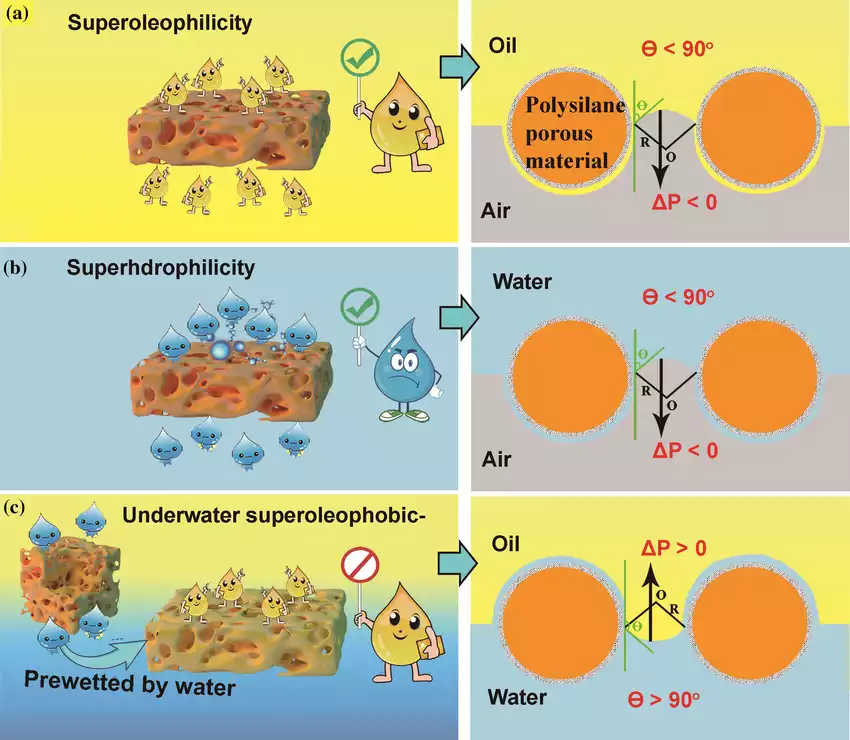

- Filtration

Filtration is to further remove the tiny impurities and turbidity left by the precipitation so that the walnut oil becomes clear and transparent. Common filtering methods are physical filtration and chemical filtration. Physical filtration is to filter out solid particles through physical methods such as filter screens and filter paper, while chemical filtration is to precipitate solid particles by adding chemical agents, and then separate the supernatant.

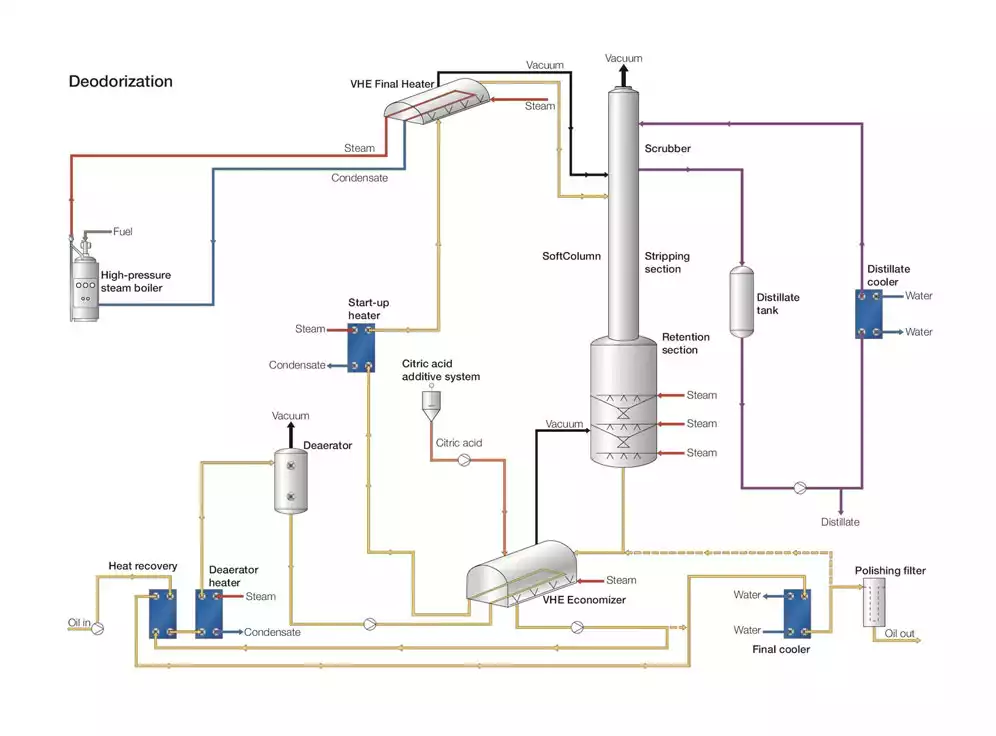

- Walnut Oil Deodorization

The filtered walnut oil also needs to deodorize processing. Deodorization is to remove the odor in the walnut oil and make the walnut oil smell more fragrant and pure. Deodorization generally uses methods such as distillation or blowing to remove substances that are not conducive to the taste and improve the quality of the oil.

- Walnut Oil Packaging

The last step is packaging. After the above series of process treatments, the walnut oil obtained needs packing. You can use containers such as glass bottles, plastic bottles, or iron barrels for packaging to ensure the storage and consumption safety of walnut oil. When packaging, it is necessary to avoid light, seal, and prevent moisture to maintain the freshness and nutritional value of walnut oil.

The above steps are the complete process of walnut oil production. Each step requires strict quality control because any link will affect the quality of the final walnut oil. Huatai Oil Machinery can provide a complete 5-3000TPD walnut oil production line of various sizes. And provides comprehensive services such as solution customization, delivery, installation, and after-sales. If you have plans to build a walnut oil processing plant, please contact us in time to get the best solution and price!

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies