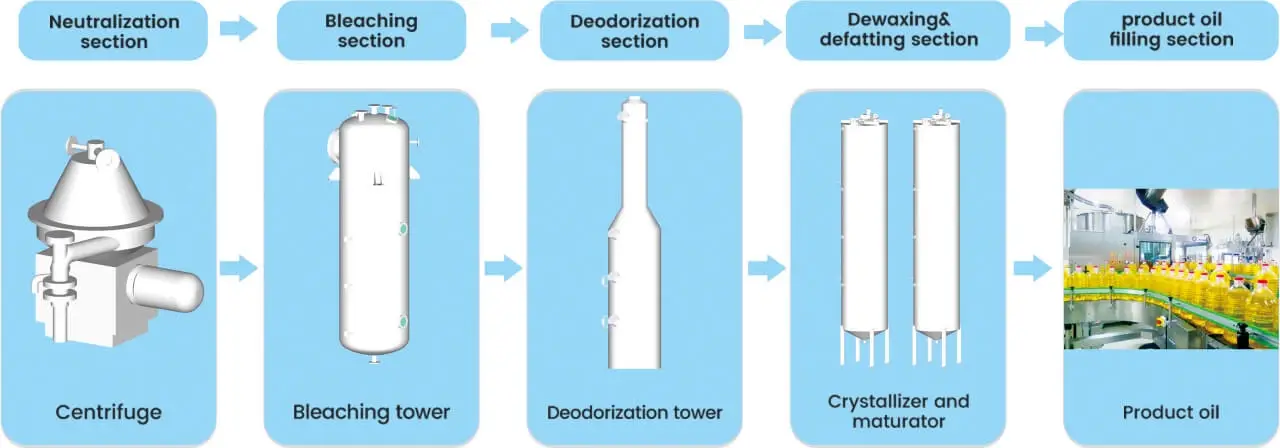

The edible oil refinery plant is the final stage in the production of cooking oil. Its job is to remove any harmful substances and impurities from the crude oil. This is important because it helps the oil last longer, smell better, and have a color that meets the standards. The refining process includes several steps: degumming (removing gum-like impurities), deacidification (getting rid of excess acidity), decolorization (clearing the oil's color), deodorization (improving the smell), dewaxing (taking out waxes that make the oil look cloudy), and fractionation (separating the oil into different parts). The exact method used depends on what kind of crude oil is being refined.

Huatai offers a variety of cutting-edge refining techniques custom to different types of edible oils. These methods include enzymatic degumming to remove gum impurities, anhydrous soap removal to purify the oil, pre-bleaching to improve color and a two-stage fatty acid capture process for further refinement.

During the decolorization stage, a special odor-capture device is used when mixing the oil with clay. This ensures that any unpleasant smells are removed, making the process environmentally friendly by preventing odor pollution.

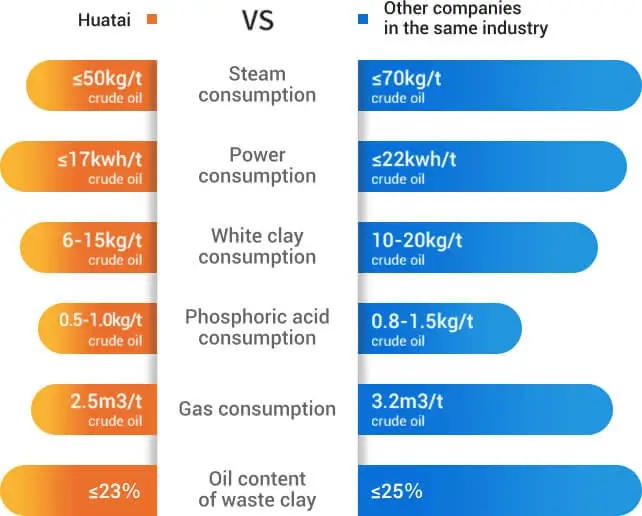

The refining workshop is highly automated, featuring full computer displays and automatic controls. This technology not only makes the process easier to manage but also uses preheating and reuse techniques to recover waste heat, which significantly reduces the need for steam.

Lastly, the vacuum system uses either freezing or chilled water, which cuts down on steam use and wastewater production. This system is beneficial because it leads to a high yield of refined oil, maintains excellent quality standards, and is efficient in terms of energy and resource consumption.

Corn germ oil refining project

Castor oil refining project

Tea seed oil refining project

Sesame oil refining project

Safflower oil refining project