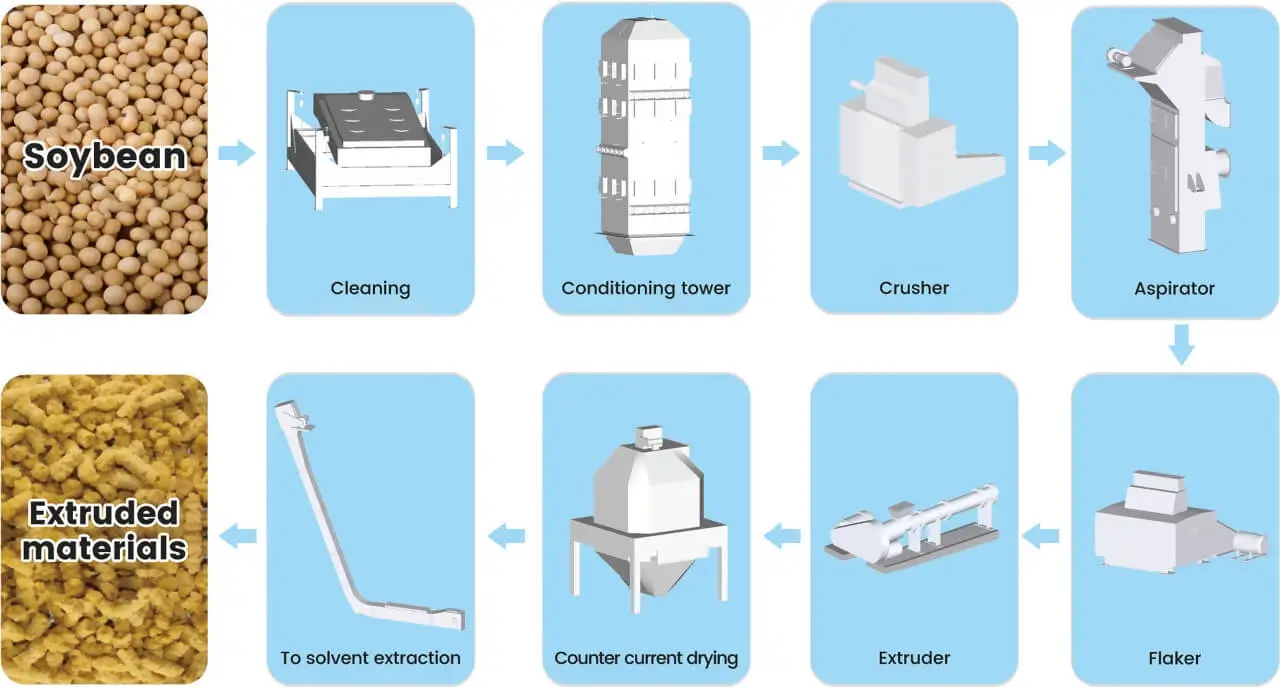

The oilseed pretreatment is the first step in oil extraction, aiming to prepare the seeds for optimal oil yield and quality. This process involves cleaning the seeds to remove impurities like small stones and metal pieces, ensuring they are in the best condition before pressing. The seeds are then flaked and cooked to enhance oil extraction efficiency. Proper pretreatment improves the quality of the extracted oil and extends the machinery's lifespan and safety. The specific steps in pretreatment—such as screening, shelling, crushing, and conditioning—vary depending on the type of oilseed and its physical properties.

The use of conveying equipment is minimized, with elevators and augers used sparingly, while scraper conveyors are preferred to reduce failure rates and extend service life.

The workshop is designed to minimize noise, featuring low-noise components, laser cutting, precise and intelligent manufacturing, and is well-equipped.

Parts of the equipment that experience material impact are designed to be wear-resistant, ensuring a long service life.

The dust removal system is well-designed, keeping the entire system in a slightly negative pressure state, and the emitted gas complies with national environmental protection standards.

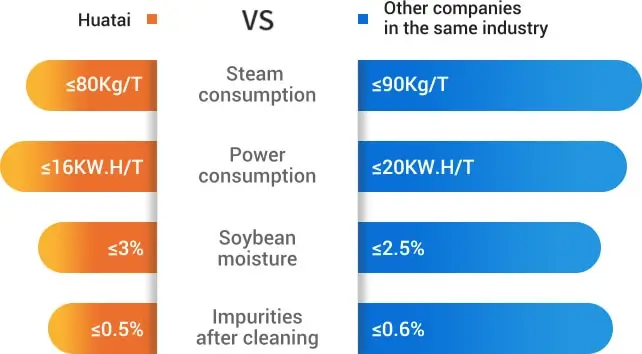

Some equipment uses frequency conversion regulation to reduce power consumption, with a reasonable power configuration that ensures low energy use.

The system features a high degree of automatic control, with a user-friendly and scientifically designed human-machine interface.

Corn germ pretreatment project

Castor seed pretreatment project

Tea seed pretreatment project

Sesame pretreatment project

Safflower seed pretreatment project

QUICK QUOTATION