Introduction

Palm oil deodorization is an important part of the palm oil refining process. In this complete guide, I will introduce you in detail to the palm oil deodorization process, influencing factors, and equipment used.

Why does palm oil need to be deodorized?

The deodorization of palm oil main purpose is to remove the bad smell in oil, such as aldehydes, ketones, hydrocarbons, low molecular weight fatty acids, glyceride oxides, white clay, residual solvents, etc.

Why does palm oil smell so bad?

Because palm oil is prone to rancidity and oxidation if the temperature and humidity are too high. These reactions will cause the unsaturated fatty acids in palm oil to decompose and produce some compounds with bad odors, which palm oil an off-flavor.

Deodorization process of palm oil

What are the methods for deodorization of palm oil?

High-temperature negative pressure deodorization method

In the deodorization equipment, heat the oil to a certain temperature (usually 230~270℃) and under negative pressure. At the same time, prompt steam injection for the evaporation and discharge of volatile substances.

Adsorption deodorization method

Mixing the adsorbent with the oil so that the adsorbent can fully absorb the bad-smelling substances in the oil. Then the adsorbent is separated from the oil by filtering and other methods.

Vacuum distillation deodorization method

In the vacuum distillation equipment, heat and evaporate the oil. Then use a condenser the evaporated oil is condensed into a liquid. And discharge the volatile substances at the same time.

Deodorization of palm oil

What is the principle of the palm oil deodorization process?

The palm oil deodorization process is usually carried out under high temperatures and negative pressure conditions. The volatile components in the oil are vaporized by heating and quickly removed in a vacuum environment to achieve the purpose of deodorization.

At the same time, high temperatures can also promote certain chemical reactions in the oil, such as oxidation reactions. However, these reactions need strict control to prevent the deterioration of oil quality.

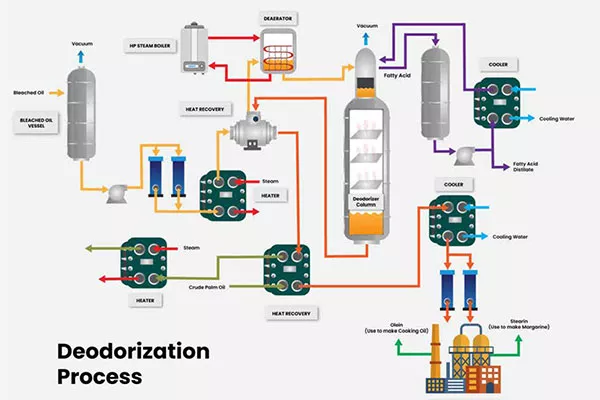

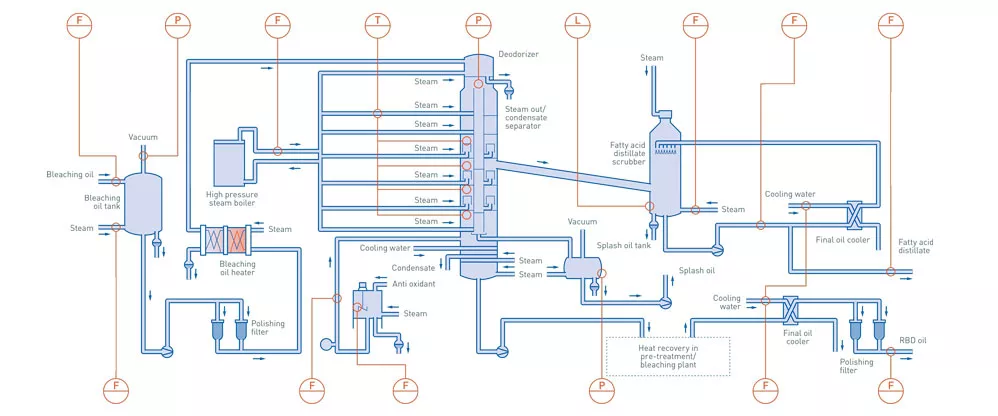

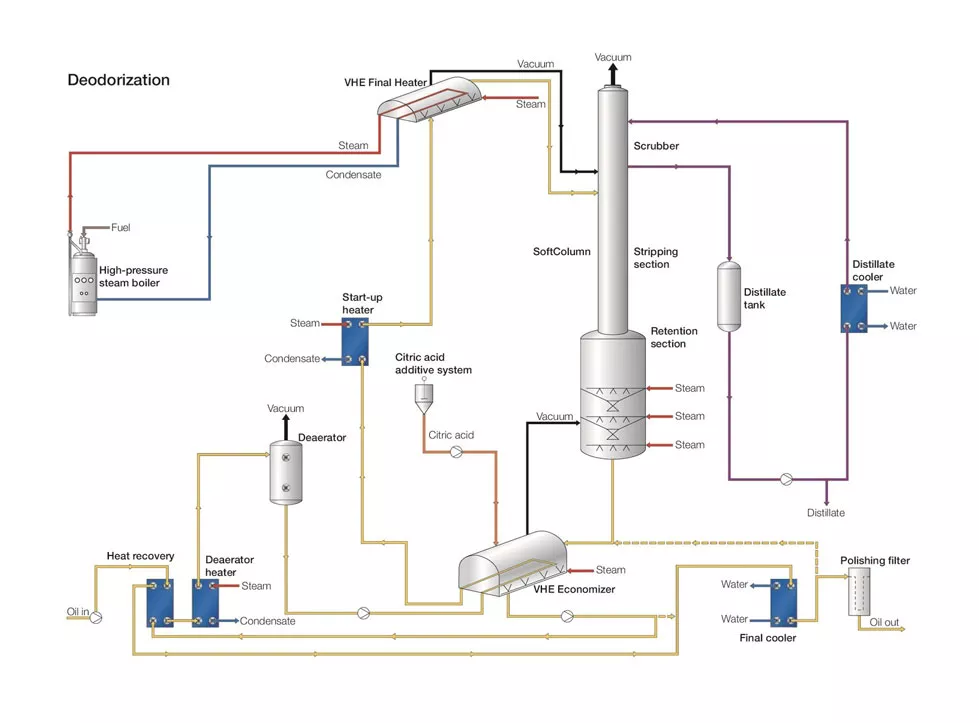

How is palm oil deodorized?

- Heating: Heat the bleached palm oil to about 200°C. This step is usually performed in a heat exchanger.

- Steam injection: Inject the steam into the deodorization tower, and remove the excess odor and taste in the oil.

- Vacuum treatment: During the deodorization process, the oil is in a high vacuum state (6~8mmHg), which helps to improve the deodorization efficiency.

- Oil clarification: The deodorized palm oil is almost transparent and odorless. At this time, the oil is clearer and of higher quality.

- By-product collection: By-products produced during the deodorization process, such as palm fatty acid distillate (PFAD). It can use in animal feed, soap production, and the oil chemical industry.

- Cooling and filtration: Cooling the deodorized oil needs to be below 70°C in time and filter to remove any residual solid particles.

Palm oil deodorization system

What are the factors of the palm oil deodorization process?

Many factors affect the palm oil deodorization process, including temperature, working pressure, steam flow, deodorization time, oil quality, equipment structure and operation, etc.

1. Temperature

Temperature is one of the most important factors in the palm oil deodorization. The deodorization temperature is usually controlled between 230~270℃.

As the temperature increases, the vapor pressure of free fatty acids and odor components will increase accordingly. Thereby improving the deodorization efficiency.

2. Working pressure

During the deodorization process, it is necessary to maintain an appropriate vacuum degree (0.27-0.40KPa). Ensure fatty acids and odor components can be fully evaporated and discharged.

When the pressure decreases, the boiling point of fatty acids and odor components also decreases accordingly. It helps to shorten the deodorization time and improve the deodorization efficiency.

3. Steam flow rate

Steam plays a key role in the palm oil deodorization process. Increasing the steam flow rate can improve the vaporization efficiency, but take care to prevent oil splashing.

It is necessary to ensure enough steam passing through the oil to bring out the volatile substances. At the same time, as the content of odor components in the oil decreases, need to increase the amount of steam.

4. Deodorization time

Generally speaking, the deodorization time needs to last for 15-120 minutes. The length of deodorization time depends on factors such as the initial quality of the oil, deodorization temperature, pressure, and steam flow rate.

5. Oil quality

The quality of the oil to be deodorized determines the initial concentration of its odor composition, which directly affects the difficulty and final effect of deodorization.

For oils of poor quality (such as rancid oils, oils containing a large amount of gel impurities, pigments, or trace metals). Need more stringent deodorization conditions or pretreatment (such as degumming, decolorization, etc.) to improve the deodorization effect.

6. Equipment structure and operation

The structure of the deodorization equipment will also affect the deodorization effect. For example, the design of shallow oil layers and thin film oil layers helps to reduce oil splashing and fraction reflux. Stainless steel materials can prevent chemical reactions when oil contacts the equipment.

During the deodorization process, it is necessary to strictly control various operating parameters (such as temperature, pressure, steam flow, etc.) and keep the equipment well sealed to avoid reduced vacuum and oil oxidation.

What equipment is used for palm oil deodorization?

Palm oil deodorization equipment mainly includes a deodorization tower, vacuum system, heating system, cooling system recovery system, etc.

The deodorization tower is the core equipment of the deodorization process. Its structural design and operating parameters have an important influence on the deodorization effect.

Conclusion

In general, the palm oil deodorization process is one of the key links in the palm oil production process. Its deodorization effect can directly affect the quality and stability of the oil.

Huatai Oil Machinery can provide complete deodorization systems for all kinds of edible oil processing plants. Our experience in the edible oil field makes us the most reliable and trusted name in machinery research, engineering, design, and manufacturing. And, we can undertake complete oil projects on a turnkey basis.

References:

- Lipid Library: https://lipidlibrary.aocs.org/edible-oil-processing/deodorization

- ScienceDirect: https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/deodorization

- Alfa Laval Inc: https://www.alfalaval.us/products/process-solutions/vegetable-oil-solutions/edible-oil-refining-process-systems/deodorization-systems/

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies