Introduction

Palm oil fractionation technology is a new palm oil processing technology. The products after fractionation are divided into olein and stearin, with olein being the most widely used. Currently, the main fractionation processes include dry fractionation, surfactant fractionation, and solvent fractionation. Among them, dry fractionation is widely applied due to its simplicity, high yield, low cost, and good product quality.

After refining, palm oil should undergo fractionation for better application. Using palm kernel oil fractionation, products with different melting points such as 8°C, 10°C, 14°C, 18°C, 24°C, 33°C, 44°C, and 55°C can be obtained.

What Is the Dry Fractionation of Palm Oil?

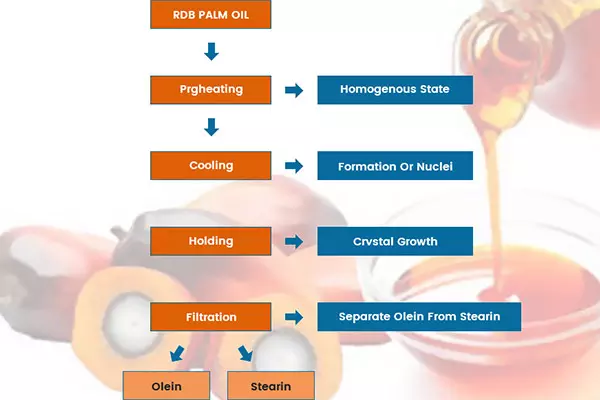

Dry fractionation of palm oil involves slowly cooling liquid palm oil to a certain temperature without adding other components, allowing crystalline solids to separate and precipitate. This method is suitable for separating triglycerides of fatty acids with similar solubility in organic solvents.

What Is the Process of Fractionation of Palm Oil?

Heating

Palm oil is semi-solid at room temperature, and its fatty acid composition is about half saturated acid (120, 140, 160.180, 200) and half unsaturated acid (161, 181182, 183). Its triglyceride composition is 8%~10% G5, about 48% G5U, 35%~39% GU2, and 7%7.5% GU3.

The unique composition of palm oil determines its special crystallization process. It is dissolved into liquid by steam heating before processing, and palm kernel oil is heated to 70~75℃ before crystallization to destroy all original crystals. The heating temperature of this process is 70~72℃.

Cooling and Crystallization

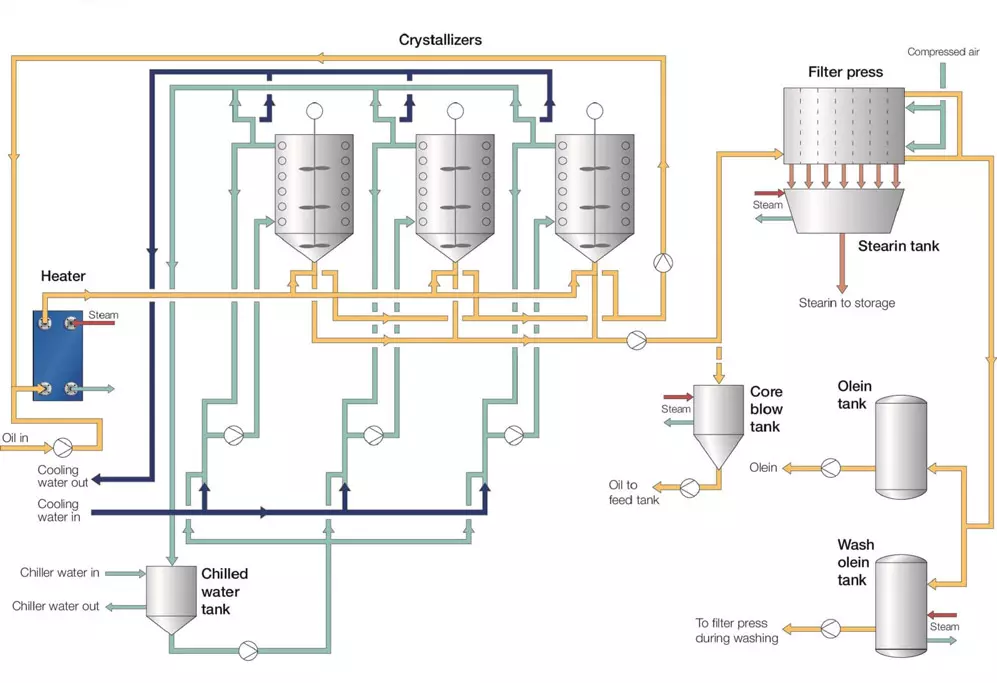

The crystallization process of palm oil control cooling the coil or jacket with water, regulating the temperature. Temperature control using temperature sensors, PLC-based temperature controllers, and control valves with positioners. (Read more: palm oil crystallization tank >>)

As cooling and crystallization are slow processes that affect multiple factors, temperature adjustments during production are crucial. Crystallization progress is monitor by observing and touching the crystals.

Filtration

Filtration equipment significantly impacts palm oil yield. You can use appropriate filtration equipment (e.g., drum filters, continuous belt vacuum filters, and membrane filters) to separate liquid oil and solid fat. Membrane filters are widely used due to their high soft fat yield (70%-75%) and high hardness of stearic acid.

In this process, you can use a fully automatic membrane filter press to filter the crystallized palm kernel oil. The hydraulic device compresses the filter plates, which consist of alternating membrane and chamber plates. The filter cloth, made of specially treated polypropylene, covers the plates to separate the filter cake and facilitate easy cleaning. The membrane material is also polypropylene, with circular flat-top protrusions on the contact part with the filter cloth to provide good filtrate channels and filter cloth support.

When the filter press closes, it forms a filter chamber between the plates. Liquid enters the filter chamber, and the filtrate passes through the filter cloth and exits through holes in the filter plates, while the filter cake remains in the filter chamber. The filter cloth and cake create resistance to the incoming oil. When resistance increases and forms a tight filter cake in the filter chamber, stop the oil feed. Then introduce a membrane squeezing medium into the membrane plates to dry the filter cake. Finally, use compressed air to blow through the filter press. After releasing the pressure, open the filter press to discharge the filter cake.

Benefits of the Huatai Dry Fractionation

- Simple process: Dry fractionation technology is relatively simple and easy to operate.

- High degree of automation: Fully automation improves production efficiency.

- Low steam consumption: Effective control of heating and cooling processes reduces steam consumption.

- Good product quality: The palm oil products obtained through dry fractionation are stable and meet national and industry standards.

Factors Affecting the Fractionation Effect of Palm Oil

- Cooling water temperature: Proper cooling water temperature control is crucial for effective crystallization.

- Filling and squeezing pressure: The pressure applied during filling and squeezing impacts the separation of liquid and solid phases.

- Filter cloth air permeability: The air permeability of the filter cloth affects the filtration efficiency. Common values are 400 and 600 L/dm²/min.

- Design of crystallizers: The design and efficiency of crystallizers play a significant role in the fractionation process.

- Palm oil quality: The initial quality of the palm kernel oil, including its variety and processing history, affects the fractionation outcome.

- Crystallization speed: The rate at which the oil cools and crystallizes can influence the size and purity of the crystals formed.

Application of Palm Kernel Oil Fractionation

Palm oil fractionation technology can be applied not only to the processing of palm kernel oil but also to animal fats, cottonseed oil, special oils, and mixed fatty acids. It can improve the added value and economic benefits of oil products. You can control the process parameters such as crystallization rate, crystallization temperature, and crystal growth time. Process different oils and fats.

Animal Fats Fractionation

Separates liquid animal fats with white color, transparency, and rich meat aroma from animal oils. Reduce cholesterol content by 50% lower than that of the original animal fat, which greatly improves the nutritional value of animal fat and has high economic value.

Cottonseed Oil Fractionation

Cottonseed oil is one of the major oils. Its fatty acid composition contains 20% to 22% palmitic acid, 30% to 35% oleic acid, and 40% to 45% linoleic acid. And a melting point of 10°C-15.6°C.

As a high-grade edible oil, cottonseed oil has a high melting point and is easy to become turbid. Its use is limited in winter and its price is low. Fractionation produces liquid and solid oils, increasing the added value and edibility of the oil. (Read more: cottonseed oil processing >>)

Special Oils Fractionation

Specialty oils such as algae oil and flaxseed oil are favored for their special nutritional components and high nutritional value. However, their high content of unsaturated fatty acids makes them prone to oxidation. Therefore requires fractionation to obtain liquid oils with rich nutrients, stable quality, and clear color.

Mixed Fatty Acid Separation

According to the length of the fatty acid carbon chain, vacuum distillation separates short carbon chains (C12), medium carbon chains (C14), and long carbon chains (C16, C18).

Conclusion

In conclusion, palm oil fractionation is an effective oil processing technology. It is separate into parts with different melting points through a simple heating, cooling, and filtering process, which has broad application prospects and market demand. Huatai undertakes various types of palm kernel oil fractionation production lines and turnkey project services. If you want to know more about palm oil fractionation, please contact us at 0086-159-3728-9608.

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies