Palm oil is the fat extracted from the pulp of the oil palm fruit, while palm kernel oil is the fat extracted from the kernel of the oil palm fruit, and they have different physical and chemical properties. Usually, one can obtain the crude palm oil (CPO) and palm meal (PE) from the palm fruit pulp through the process of boiling, crushing and pressing. Meanwhile, in the process of crushing, the fruit of the palm (i.e. palm kernel) is separated, then crushed and the shell removed, and the remaining kernel is pressed to obtain the gross palm kernel oil (CPKO) and palm kernel meal (PKE). (Read more: How is palm oil made >>)

Palm oil is also known as saturated fat because it contains 50% saturated fat. The human body digests and absorbs more than 97% of palm oil. Like all other vegetable cooking oils, palm oil itself contains no cholesterol. The most suitable area for growing oil palm is the tropical region between 5 degrees north and south latitude of the equator. Malaysia is the world's largest producer and exporter of palm oil. Its production accounts for about half of the world's total production and exports account for about 70% of the world's total.

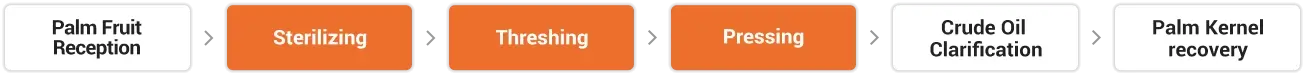

Palm Fruit Bunches (also known as FFB, or Fresh Fruit Bunches) collected from palm plantations are weighed on a weighbridge to clarify their weight before entering the mill and are subsequently sent to the unloading table to await subsequent processing.

The palm fruit bunches are then subjected to sterilization. Typically, this step is carried out in the kill tank, where high temperature cooking is achieved by injecting steam. The main purpose of sterilization is to avoid enzymatic decomposition, thus preventing an increase in the acidity of the palm fruit, which would affect the quality of the palm oil.

Next, the palm fruits are separated from the bunches. This step is usually carried out using a drum thresher, which replaces the traditional manual threshing method and greatly improves the threshing efficiency. After threshing, the palm fruits move on to the next process, while the empty bunches can be treated as fertilizer.

After threshing, the palm fruits are further cooked to break down the cellular structure of the pulp and make it easier to press the oil. After cooking, the palm fruits are fed into a screw press machine, from which palm oil is extracted by means of mechanical rotary pressing. The pressing process produces a mixture of oil, water, solid impurities and a mixture of fibers and kernels (i.e. press cake).

Gross palm oil is separated from the press cake and other impurities are removed by clarification equipment. This step is essential to improve the quality of palm oil. Typically, rotary sieves, sedimentation tanks and plate and frame filters are used in the clarification process, and multiple filtrations ensure that impurities are effectively removed from the crude palm oil.

In this step, the palm kernel is separated from the press cake by means of specific processes and equipment for subsequent processing (e.g. production of palm kernel oil, etc.). It is important to note that palm kernel recovery is not a mandatory part of the palm oil production process, but varies according to production needs and product type.

Palm oil refining can be categorized into three types: Batch Refinery, Semi-continuous Refinery, and Continuous Refinery. For small-scale production ranging from 1 to 20 tons per day (TPD), the Batch Refinery is the best fit. Medium to large-scale production, from 20 to 50 TPD, suits the Semi-continuous Refinery, while the Continuous Refinery is designed for very large operations, handling 50 to 600 TPD.

Huatai Oil Machinery provides complete solutions for palm oil production lines, including refining crude palm oil. We offer various types of refineries, from small batch plants to large, continuous operations. The refining process includes degumming, deacidification, bleaching, and deodorization, each crucial for achieving high-quality palm oil.

GET A QUOTEThe CPO refining process mainly includes four steps of degumming, deacidification, bleaching and deodorization.

Both degumming and deacidification are used to remove free fatty acids, protein mixtures, trace metals, and other impurities from the gross palm oil that can affect the quality and stability of the palm oil. The chemical refining method of deacidification is to add caustic soda live soda ash to the gross palm oil, so that the free fatty acids and its neutralization reaction, the formation of soap foot and glycerol.

The palm oil bleaching process removes pigments and other impurities from the crude palm oil and improves the color and flavor of the oil. We can remove pigments dissolved in the oil or pigments dispersed in the oil in the form of colloidal particles and other impurities according to the strong selective adsorption effect of activated white clay and activated carbon on pigments.

To remove the odor and bad smell in the crude palm oil, we can heat the crude palm oil to 230~265℃ and pass high temperature steam under vacuum conditions, so that the odor and volatile matter in the oil will escape with the steam. Then the deodorized oil is cooled and filtered.

The palm oil fractionation plant can process between 1 to 500 tons per day. This plant enhances the value of palm oil by separating it into different components based on melting points.

Huatai uses state-of-the-art technology for fractionation. This includes sophisticated crystallization and filtration systems, along with precise temperature control software. The result is a separation of palm olein and palm stearin, yielding fractionated products with distinct melting points such as 18°C, 24°C, and 32°C. This process is essential for producing palm oil products with specific characteristics and applications.

Due to the toughness of palm nut shells, pressing them without separating the kernels and shells first can cause rapid wear and tear on the machinery. To prevent this, we use a palm kernel cracker and separator machine. This equipment efficiently cracks the nuts and separates the kernels from the shells. Simply load the palm nuts into the machine, and watch as the kernels and shells are separated and discharged from different outlets.

The equipment for extracting palm kernel oil includes a series of machines: a cleaning sieve to remove dirt, a stone removal machine to pick out stones, a magnetic selector to catch metal pieces, a crushing machine to break down the kernels, a separation machine to divide the kernel and shell, a dryer, a frying machine to prepare the kernels for oil extraction, a press to extract the palm oil, and a filtration machine to purify the crude palm kernel oil.

Huatai is an expert in Palm Oil and Palm Kernel Oil Processing Plants, offering complete solutions for setting up a Palm Oil Processing Plant. Our team of professionals is dedicated to designing the entire plant to help you make the best use of the by-products of palm oil production and ensure maximum profitability for your business. We also provide complete turnkey projects according to your needs.

Huatai's palm oil processing plants can handle between 3 and 120 tons per hour. With over three decades of experience, we can provide detailed design services, installation assistance, and machine operating instructions for palm oil production lines. Please feel free to contact us if you have any requirements for palm oil, palm kernel oil processing machines, or refining equipment.

Discover the world of palm oil production with Huatai oil machinery! Whether you're dealing with a bounty of palm fruit or looking to streamline your oil processing, we've got you covered. Dive into our comprehensive palm oil production solutions, from start to finish. We offer a full range of equipment custom to your needs: from pretreatment to extraction, to refining. Embark on a seamless palm oil turnkey.

GET A QUOTE