Introduction

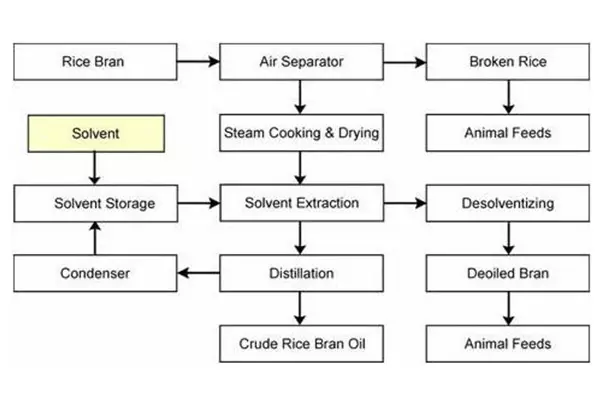

The rice bran oil solvent extraction process is a safe and technologically advanced method for processing cooking oil based on chemical extraction theory. This process can extract 99% of the oil from rice bran, making it highly efficient. Due to the low oil content in rice bran, most factories use this method for its large output and high economic benefits. (Read more: rice bran oil refinery plant. >>)

Four Steps of Rice Bran Oil Solvent Extraction

Step1: Rice Bran Oil Extraction

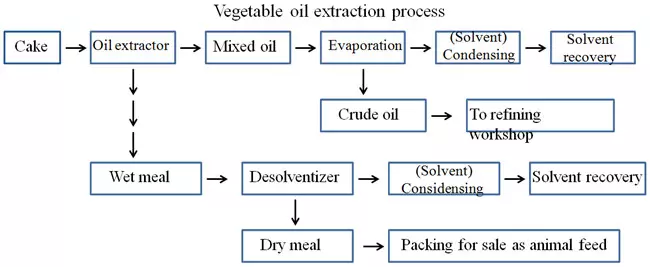

In this initial step, the rice bran is mixed with a solvent, typically hexane, in an oil extractor. The solvent dissolves the oil present in the rice bran, creating a mixture known as “miscella” (mixed oil). This process results in two primary outputs: a wet meal (the solid residue) and the miscella. The efficiency of this extraction depends on factors such as the quality of the rice bran and the effectiveness of the solvent.

Step2: Wet Meal Desolventization

The wet meal, which still contains some solvent, is then processed in a Desolventizer-Toaster-Dryer-Cooler (D.T.D.C.) system. This system performs multiple functions:

- Desolventizing: The wet meal is heated to evaporate the solvent, which is then collected for reuse.

- Toasting: The meal is subjected to high temperatures to deactivate any remaining enzymes and reduce anti-nutritional factors.

- Drying: The meal is dried to reduce its moisture content.

- Cooling: Finally, the meal is cooled to a safe temperature for storage and handling.

The result is a dry meal that is free of solvent and can be used as animal feed.

Step3: Mixed Oil Evaporation and Stripping

Then, the miscella (mixed oil) undergoes further processing to separate the solvent from the rice bran oil. This involves:

- First Evaporation: The miscella is heated in the first evaporation machine, causing the solvent to evaporate. The vaporized solvent is then condensed and collected.

- Second Evaporation: The partially purified rice bran oil undergoes a second evaporation to remove any remaining solvent.

- Stripping Tower: Then the rice bran oil is passed through a stripping tower where steam is used to strip off any residual solvent. Ensuring that the final product is pure rice bran oil.

Step4: Solvent Cooling and Recycling

Finally, the solvent recovered from the D.T.D.C. system, evaporation machines, and stripping tower is cooled and recycled for reuse in the extraction process. This recycling is crucial for both economic and environmental reasons. As it reduces the need for fresh solvents and minimizes waste.

Features of the Rice Bran Oil Solvent Extraction Process

Versatile Extractors

The rice bran oil solvent extraction process offers flexibility with various types of extractors, each suited to different production capacities and operational needs. The following are three different oil solvent extraction equipment provided by Huatai:

- Rotocel Extractor: This is a continuous extractor that is highly efficient for large-scale operations. It features a rotating cell design that ensures thorough extraction and minimal solvent loss.

- Loop Type Extractor: Known for its simplicity and reliability, the loop type extractor is suitable for medium to large-scale operations. It operates in a loop, allowing for continuous feeding and discharge of materials.

- Drag Chain Extractor: Ideal for smaller capacities, the drag chain extractor uses a chain mechanism to move the rice bran through the extraction process. It is compact and efficient, making it a good choice for facilities with limited space.

High Efficiency

The Huatai Oil Machinery rice bran oil solvent extraction process is designed for high efficiency, primarily due to its automation and advanced technology.

- Automation: Automated systems control various stages of the extraction process, ensuring consistent operation and reducing the need for manual intervention. This leads to lower labor costs and minimizes human error.

- Energy Consumption: The process is optimized to use energy efficiently, reducing overall production costs. Heat recovery systems and energy-efficient equipment contribute to this high efficiency.

High Oil Yield

The Huatai rice bran oil extraction process can achieve a high oil yield and meal.

- Residual Oil Content: The process is designed to extract the maximum amount of oil from the rice bran, leaving less than 1% residual oil in the meal. This high extraction efficiency ensures that the maximum possible oil is obtained from the raw material.

- Quality of Residual Meal: The meal left after oil extraction is of high quality and contains minimal oil. Making it an excellent source of animal feed. This not only adds value to the by-products but also supports sustainable practices by utilizing all parts of the raw material.

Conclusion

By following these steps, the rice bran oil solvent extraction process efficiently produces high-quality oil. And while ensuring that the solvent is effectively recovered and reused. This method is widely used in the industry due to its efficiency and cost-effectiveness. If you are planning to build a rice bran oil processing plant, contact Huatai Oil Machinery. We offer high-quality rice bran oil solutions and excellent services to meet your needs.

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies