Soybean Oil Extraction Machine

The oil content of soybeans is relatively low, generally 15%~26%. To improve the oil recovery rate, use solvent extraction. The pressed soybean flakes are placed in an extractor, and an appropriate amount of solvent is added for continuous extraction. We usually use hexane as solvent (also known as No. 6 solvent oil), because it has good solubility and volatility, and can effectively extract the oil from soybeans. The solvent will dissolve the oil in the soybeans to form an oil-solvent mixture, which is called a mixed solution. (Learn more: soybean oil solvent extraction >>)

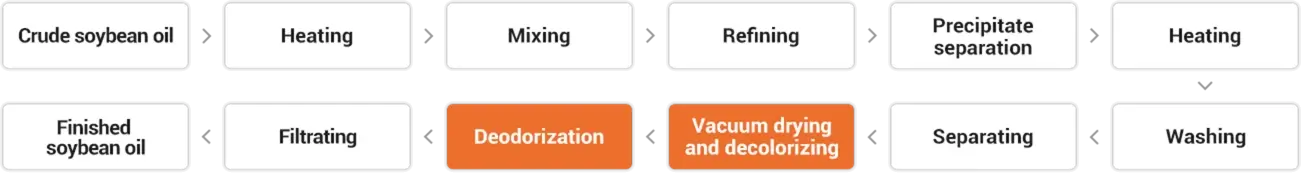

Extraction Process:

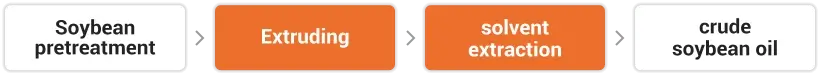

Soybean Extruding Process

The soybean extrusion process is to physically extrude soybeans through an oilseed extruder to form porous expanded particles. Under the action of the extruder, the oil or other components in the soybeans are released. At this time, the temperature in the extruder ranges from 110℃~200℃, and the extrusion time is 1~3 minutes.

Huatai YJP series oil seeds extrusion extruder has a daily output of 60-1800 tons. It is an important equipment for vegetable oil factories to improve production and quality and reduce consumption and can be applied to various oils.