Introduction

Soybean oil, derived from soybean oilseeds, is a versatile and widely used oil in cooking and food production. The process of refining crude soybean oil into a refined, high-quality product involves several stages. In this article, we’ll explore the detailed steps of soybean oil refining and the benefits of Huatai’s soybean oil refinery plant. (Read more: soybean oil processing plant>>)

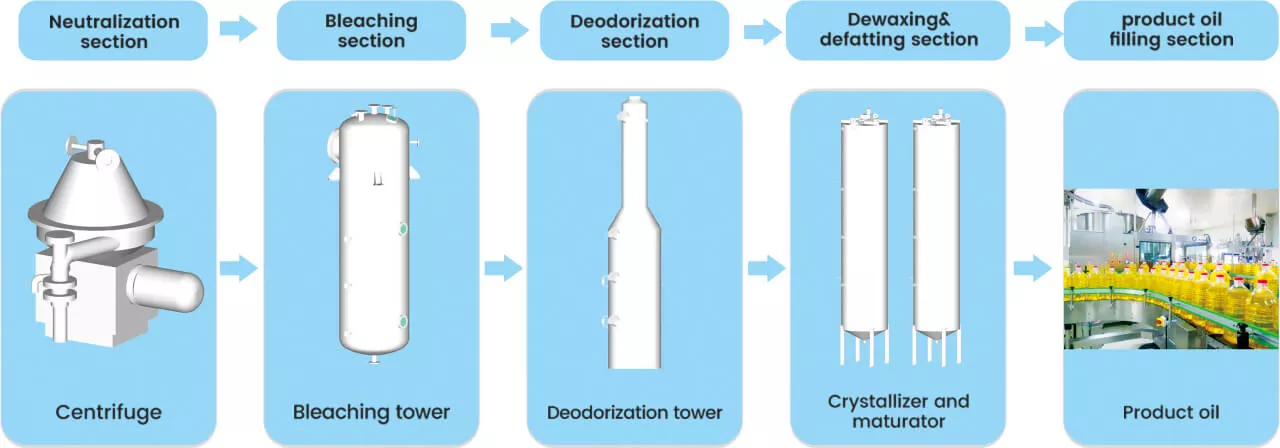

Soybean oil refining process

Understanding the Soybean Oil Refining Process

Soybean oilseeds are first crushed into flakes, and crude soybean oil is extracted using an extraction machine system. This crude oil requires further processing to remove impurities and enhance its quality. (Read more: how is soybean oil made >>)

1. Degumming

Degumming is the first step in refining soybean oil, where phosphatides are removed. The process involves mixing the crude oil with hot water at 65 to 70°C, allowing the gums to separate. The mixture is then processed through centrifuges to separate the heavy phase (gums) from the light phase (degummed oil). This stage removes hydratable phosphatides up to 600 ppm, resulting in soya gums, which contain lecithin, cephalin, and inositol.

Crude soybean oil degumming

2. Neutralization and Water Washing

Next, free fatty acids (FFA), remaining phosphatides, chlorophyll, and carotenes are eliminated. The degummed oil is reheated to 85-90°C, and 85% commercial-grade phosphoric acid is added. This converts non-hydratable phosphatides into a precipitate. Caustic soda is then added based on the FFA content. The mixture is processed through centrifuges to separate soap stock and non-hydratable phosphatides. The resulting neutral oil contains some soap particles, which are removed by reheating the oil to 95°C, mixing it with hot water, and separating it again using centrifuges. The oil is then dried to remove moisture.

3. Bleaching

Bleaching removes soap particles, phosphorous, and color pigments using activated bleaching earth and activated carbon. The oil from the neutralization process is heated to 105°C and mixed with bleaching agents. This mixture undergoes a three-stage bleaching process under vacuum to ensure proper absorption and removal of impurities. The oil is then filtered using pressure leaf filters to obtain bleached oil. (Read more: oil bleaching process >>)

4. Deodorization

Deodorization involves heating the bleached oil to 120°C, removing air contamination, and further heating it to 240-250°C. The oil is then fed into a deodorizer, where FFA and other odoriferous materials are stripped off using steam. This process lasts about 60 minutes and ensures the removal of any remaining impurities. The deodorized oil is cooled to below 55°C and tested for quality parameters like peroxide value. Finally, citric acid and vitamins are added to the oil, making it ready for human consumption.

Crude soybean oil deodorization

Soybean Oil Refinery Machine Technical Specifications

| Specification | Details |

|---|---|

| Capacity Range | 5 – 500 Tons Per Day |

| Refining Process | Batch Type System |

| Water Consumption | ≤ 700 Liters / Ton of oil |

| Electrical Consumption | ≤ 20 KWH / Ton of oil |

| Steam Consumption | ≤ 180 Kg / Ton of oil |

| Diesel Consumption | ≤ 40 Liters Per Hour of Boiler Running |

| Clay Amount | ≤ 8 to 12 Kg / Ton of oil |

| Degumming Agent | 400 to 700 Grams / Ton of oil |

| Circulating Cooling Water | ≈ 100 M3/h |

Set up Soybean Oil Refinery Plant Cost

| Refinery Size (T/D) | Type of Refinery | Estimated Cost (USD) |

|---|---|---|

| 1-20 T/D | Batch Type | $100,000 – $500,000 |

| 20-50 T/D | Semi-Continuous Type | $500,000 – $1,500,000 |

| 50-100 T/D | Semi-Continuous Type | $1,500,000 – $3,000,000 |

| 100-300 T/D | Full-Continuous Type | $3,000,000 – $10,000,000 |

| 300-500 T/D | Full-Continuous Type | $10,000,000 – $20,000,000 |

| 500-1000 T/D | Full-Continuous Type | $20,000,000 – $50,000,000 |

Benefits of Huatai’s Soybean Oil Refining Plant

- Less Oil Loss: Efficient processes ensure minimal oil loss during refining.

- High Stability: The refined oil has high stability, making it suitable for various uses.

- Versatile Processing: Suitable for oil with high acid value and low gum impurity.

- Effective FFA Removal: More free fatty acids are distilled out, enhancing oil quality.

Huatai soybean oil refinery plant

Conclusion

Huatai’s soybean oil refinery plant offers a robust, versatile, and reliable solution for refining crude soybean oil into high-quality refined oil. With proven technology that is energy-efficient and environmentally friendly, Huatai ensures economical and efficient oil refining. If you want to know more about soybean oil refinery, please contact us at 0086-159-3728-9608.

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies