Why choose a sunflower oil press machine?

The sunflower oil press machines are gaining popularity, especially in rural areas and among household users. Why? Because they’re a fantastic way to make the most out of your sunflower harvest.

- Portability: These machines are lightweight and easy to move around. No need for heavy lifting or complex setups.

- Low Cost: Starting your sunflower oil business doesn’t have to break the bank. Small oil-making machines are budget-friendly, reducing your investment risk.

- Ease of Operation: Designed with user-friendly controls, even a newbie can operate these machines without a hitch.

- Energy Efficiency: With lower power requirements, these machines save on energy and cut down your costs.

- Fresh Sunflower Oil: Extracting oil directly as needed means you get the freshest, highest-quality sunflower oil every time.

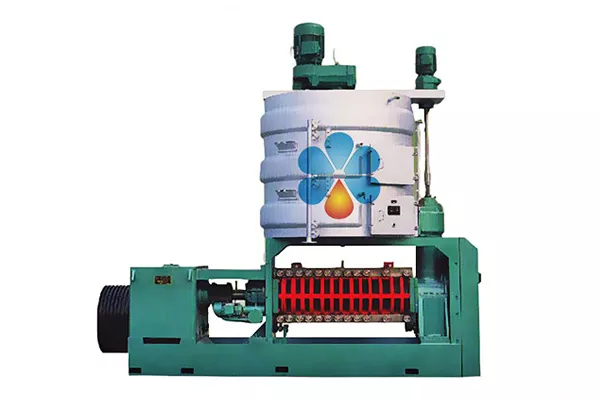

Sunflower oil press: Construction & Principle

Let’s get a bit technical and explore how these machines work. Here’s a breakdown of its main components:

- Feeding System: This includes a feeding hopper and a feeding screw. The hopper holds the sunflower seeds, and the screw pushes them into the pressing chamber.

- Pressing System: The core of the machine, it consists of a pressing screw and a pressing chamber. The screw’s design helps in efficiently extracting the oil from the seeds.

- Heating System: To improve oil fluidity and enhance the extraction process, the pressing chamber is heated using electric or steam heaters.

- Control System: This monitors and adjusts operational parameters like temperature, pressure, and speed, ensuring optimal oil extraction efficiency.

Types of sunflower oil press machines

When it comes to choosing the right sunflower oil press machine, you’ll generally encounter two main types: the conventional screw type and the automatic press with a vacuum filter. Let’s compare them.

Conventional Screw Type

This includes a feeder, gearbox, pressing cage, screw shaft, and extraction stand. It’s straightforward, cost-effective, and easy to operate.

Automatic Press with Vacuum Filter

This advanced model simplifies the process further. It includes an electric control system, heating system, vacuum filter drum, and oil sight glass. Though a bit pricier, it offers better oil yield and is quicker to set up.

Conclusion

If you’re in the market for an efficient, cost-effective solution to your sunflower oil needs, the Huatai sunflower oil processing plant is your best bet. Plus, they’re easy on the wallet and simple to operate. Ready to take the plunge? Start squeezing the best out of your sunflower seeds today!

Get your best price

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

30 years+ of oil mill plant R&D

More than 56 innovative technologies