- Dehulling

- Shelling

- Pressing

-

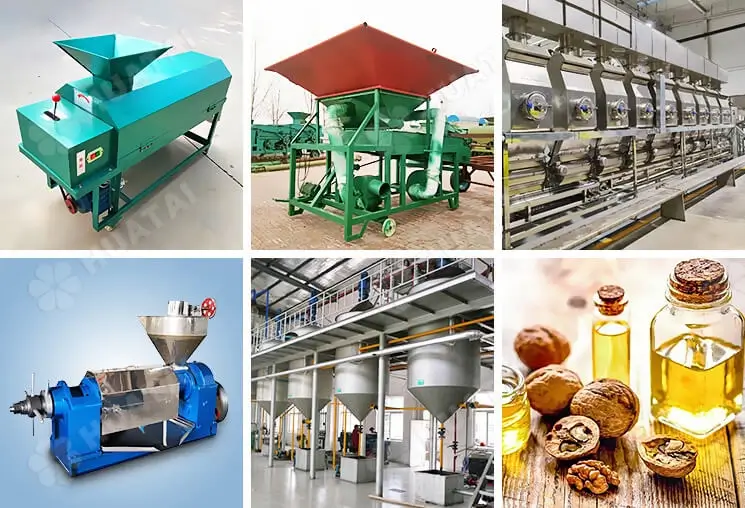

Walnut Dehulling

Freshly harvested walnuts are placed into a dehulling machine, which not only removes the tough outer hulls but also washes the nuts. It uses a fast-spinning hob to slice off the hulls, while any remaining pieces are brushed away by a steel brush. After dehulling, the walnuts are thoroughly washed to eliminate any surface mucus.

GET A QUOTE -

Walnut Shelling

Once dehulled, the walnuts are sorted by size using a grading machine. Next, they're cracked open in a shelling machine that uses rollers to gently break the shells. This process separates the valuable walnut kernels from their hard shells.

GET A QUOTE -

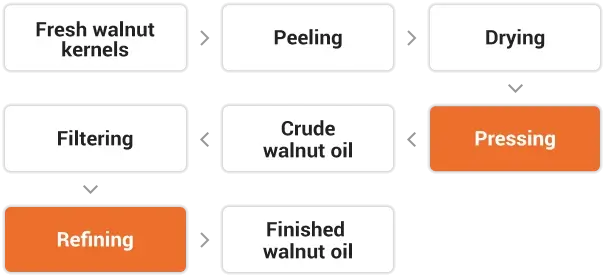

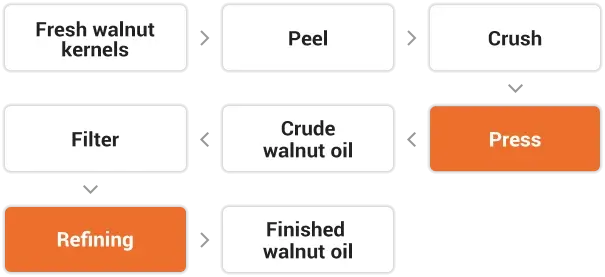

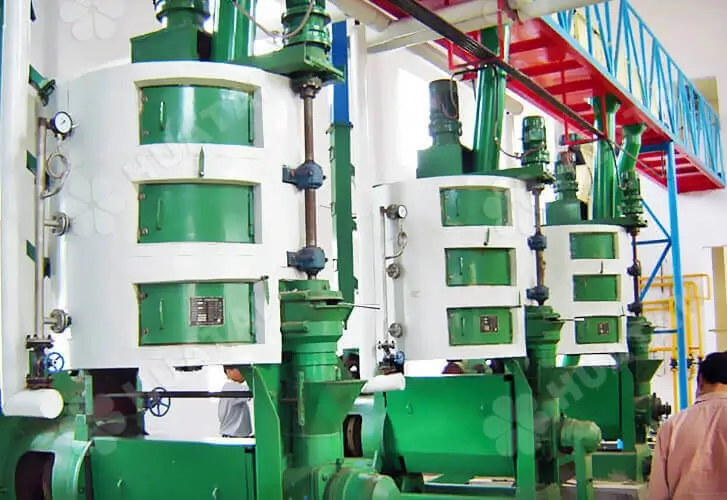

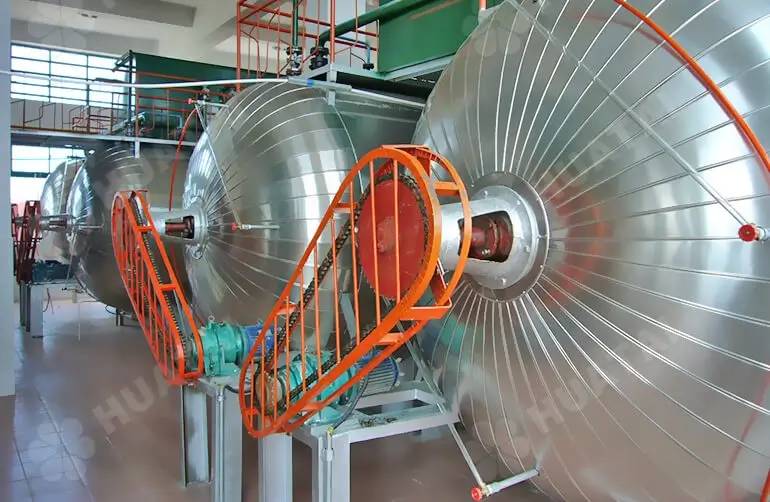

Walnut Pressing

To extract the oil, the walnut oil production line can employ various methods such as cold pressing, hot pressing, or a combination of both, known as double pressing. These techniques are designed to maximize oil yield while maintaining the highest quality of the walnut oil produced.

GET A QUOTE